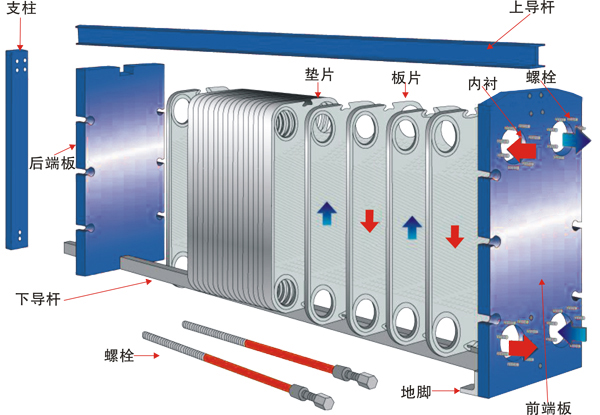

Detachable plate heat exchanger

|

The clamping bolt system consists of a bearing box system, a bolt and a locking system. The bearing housing system allows the bolts to be quickly and accurately seated and easily tightened, and the locking system prevents the bolts from rotating when tightened. All bolts are rolled and coated with anti-corrosion materials and lubricating oil, plastic cover with outer cover, heavy hex nuts make the whole disassembly process easy, and all clamping bolts can be removed and installed from the side for easy disassembly, clamping bolts The design is easy to disassemble.

|

|

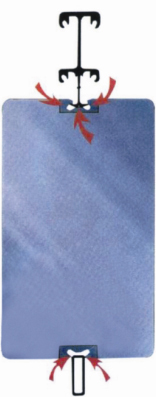

The clamping bolt system consists of a bearing box system, a bolt and a locking system. The bearing housing system allows the bolts to be quickly and accurately positioned and easily tightened. The locking system prevents the bolts from tightening when the detachable plate heat exchanger uses a precise multi-point positioning system. The four-corner positioning system with a corner hole diameter of 100mm or less allows the upper and lower guide rods to be precisely fitted together. The five-point positioning system of the angle hole direct release 150mm or more allows the positioning of the plate to be determined by a plurality of metal-to-metal contact points, wherein the contact point of the upper guide bar prevents the plate from moving up and down, and the lower guide bar contacts. The point can limit the movement of the sheet from left to right. The multi-point positioning technology allows the plate group to move back and forth without any resistance on the guide bar. It is easy and simple to complete the maintenance work, and the plate can be properly assembled during the reassembly, so that the gasket is sealed accurately. Poor, the plate group reached a full reset. This ensures that the life of the heat exchanger is long after disassembly and assembly. Moreover, the plate heat exchanger with multi-point positioning system only needs one person. Even without any experience, the heat exchanger can be easily disassembled with a simple tool, which is unmatched by other plate heat exchanger products. Turn. All bolts are rolled and coated with anti-corrosion materials and lubricating oil, plastic cover with outer cover, heavy hex nuts make the whole disassembly process easy, and all clamping bolts can be removed and installed from the side for easy disassembly, clamping bolts The design is easy to disassemble. |

| Bink 6 series detachable plate heat exchanger product specification data sheet | |||||||||||

| 6 series product model | Take over | Area | Max pieces | Max flow | Plate thickness | Product height | Product width | Plate height | Plate width | Corner hole spacing | Clamping size |

| m³/h | mm | mm | mm | mm | mm | mm | mm | ||||

| BK25-601 | DN32 | 0.094㎡ | 320 | 15 | 0.5/0.6 | 790 | 190 | 739 | 125 | 668*60 | N*(2.5+X) |

| BK25-602 | DN32 | 0.04㎡ | 80 | 15 | 0.5/0.6 | 480 | 180 | 429 | 125 | 357*60 | N*(2.5+X) |

| BK20-603 | DN50 | 0.11㎡ | 80 | 36 | 0.5/0.6 | 737 | 245 | 643 | 193 | 553*100 | N*(2.0+X) |

| BK30-604 | DN50 | 0.10㎡ | 60 | 36 | 0.5/0.6 | 737 | 245 | 642 | 192 | 553*100 | N*(3.0+X) |

| BK20-605 | DN50 | 0.19㎡ | 280 | 36 | 0.5/0.6 | 920 | 320 | 747 | 248 | 640*140 | N*(2.0+X) |

| BK30-606 | DN50 | 0.18㎡ | 200 | 36 | 0.5/0.6 | 920 | 320 | 747 | 248 | 640*140 | N*(3.0+X) |

| BK20-607 | DN50 | 0.33㎡ | 280 | 36 | 0.5/0.6 | 1294 | 320 | 1148 | 248 | 1036*140 | N*(2.0+X) |

| BK40-608 | DN65 | 0.15㎡ | 140 | 60 | 0.5/0.6 | 704 | 400 | 506 | 329 | 380*203 | N*(4.0+X) |

| BK20-609 | DN80 | 0.23㎡ | 310 | 90 | 0.5/0.6 | 890 | 400 | 748 | 329 | 606*196 | N*(2.0+X) |

| BK30-610 | DN80 | 0.21㎡ | 200 | 90 | 0.5/0.6 | 890 | 400 | 748 | 329 | 606*196 | N*(3.0+X) |

| BK25-611 | DN100 | 0.30㎡ | 380 | 145 | 0.5/0.6 | 1084 | 470 | 871 | 371 | 719*225 | N*(2.5+X) |

| BK40-612 | DN100 | 0.28㎡ | 270 | 145 | 0.5/0.6 | 1084 | 470 | 871 | 371 | 719*225 | N*(4.0+X) |

| BK20-613 | DN100 | 0.63㎡ | 650 | 145 | 0.5/0.6 | 1881/1923 | 480 | 1499 | 371 | 1338*225 | N*(2.0+X) |

| BK25-614 | DN100 | 0.63㎡ | 460 | 145 | 0.5/0.6 | 1881/1923 | 480 | 1499 | 371 | 1338*225 | N*(2.5+X) |

| BK25-615 | DN150 | 0.75㎡ | 690 | 320 | 0.5/0.6 | 1815/1940 | 610/650 | 1498 | 498 | 1294*298 | N*(2.5+X) |

| BK40-616 | DN150 | 0.75㎡ | 410 | 320 | 0.5/0.6 | 1815/1940 | 610/650 | 1498 | 498 | 1294*298 | N*(4.0+X) |

| BK25-617 | DN150 | 1.38㎡ | 690 | 320 | 0.5/0.6 | 2752 | 610/637 | 2250 | 498 | 2035*288 | N*(2.5+X) |

| BK20-618 | DN200 | 1.13㎡ | 680 | 570 | 0.5/0.6 | 2105 | 780 | 1749 | 621 | 1478*353 | N*(2.0+X) |

| BK40-619 | DN200 | 1.06㎡ | 400 | 570 | 0.5/0.6 | 2105 | 780 | 1745 | 620 | 1478*353 | N*(4.0+X) |

| BK30-620 | DN200 | 1.11㎡ | 680 | 570 | 0.5/0.6 | 2165/2105 | 780 | 1749 | 621 | 1478*353 | N*(3.0+X) |

| BK40-621 | DN200 | 0.45㎡ | 290 | 570 | 0.5/0.6 | 1405 | 740 | 961 | 621 | 698*363 | N*(4.0+X) |

| BK25-622 | DN250/DN200 | 1.88㎡ | 940 | 890 | 0.5/0.6 | 2595/2895 | 920 | 2246 | 746 | 1939*439 | N*(2.5+X) |

| BK40-623 | DN250/DN200 | 1.85㎡ | 630 | 890 | 0.5/0.6 | 2595/2895 | 920 | 2246 | 746 | 1939*439 | N*(4.0+X) |

| BK33-624 | DN300/DN350 | 2.30㎡ | 720 | 1300 | 0.5/0.6 | 2882/3082 | 1150/1170 | 2245 | 995 | 1842*596 | N*(3.3+X) |

| BK33-625 | DN300/DN350 | 2.32㎡ | 910 | 1800 | 0.5/0.6 | 2875 | 1174 | 2757 | 998 | 2336*578 | N*(3.3+X) |

| BK25-626 | DN350/DN300 | 2.70㎡ | 1360 | 1800 | 0.5/0.6 | 3210 | 1154 | 2598 | 998 | 2177*578 | N*(2.5+X) |

| BK33-627 | DN350/DN300 | 1.56㎡ | 910 | 1800 | 0.5/0.6 | 2375 | 1174 | 2257 | 998 | 1433*578 | N*(3.3+X) |

|

Remarks: 1. The above product data is for reference only. The accurate product data is subject to the product design book and product drawings issued by our company. 2, the above products are the main product series of our company, our company can also provide other models of various models, please contact our technical department for consultation. |

|||||||||||

| Bink 8 series detachable plate heat exchanger product specification data sheet | |||||||||||

| 8 series product model | Take over | Area | Max pieces | Max flow | Plate thickness | Product height | Product width | Plate height | Plate width | Corner hole spacing | Clamping size |

| m³/h | mm | mm | mm | mm | mm | mm | mm | ||||

| BK26-801 | DN32 | 0.05㎡ | 80 | 15 | 0.5/0.6 | 570 | 180 | 550 | 129 | 480*61 | N*(2.6+X) |

| BK30-802 | DN50 | 0.15㎡ | 100 | 36 | 0.5/0.6 | 920 | 290 | 780 | 212 | 691*118 | N*(3.0+X) |

| BK33-803 | DN80 | 0.30㎡ | 200 | 90 | 0.5/0.6 | 1178.5 | 425 | 999 | 337 | 868*212 | N*(3.3+X) |

| BK39-804 | DN80 | 0.30㎡ | 270 | 90 | 0.5/0.6 | 1178.5 | 425 | 999 | 337 | 868*212 | N*(3.9+X) |

| BK39-805 | DN100 | 0.46㎡ | 270 | 145 | 0.5/0.6 | 1440 | 425 | 1400 | 425 | 1227*257 | N*(3.9+X) |

| BK32-806 | DN100 | 0.30㎡ | 340 | 145 | 0.5/0.6 | 1110 | 540 | 897 | 445 | 707*262 | N*(3.2+X) |

| BK32-807 | DN100 | 0.52㎡ | 470 | 145 | 0.5/0.6 | 1515/1547 | 540 | 1303 | 445 | 1113*262 | N*(3.2+X) |

| BK32-808 | DN100 | 0.76㎡ | 480 | 145 | 0.5/0.6 | 1953 | 540 | 1709 | 445 | 1519*262 | N*(3.2+X) |

| BK32-809 | DN150 | 0.62㎡ | 490 | 320 | 0.5/0.6 | 1507/1606 | 640 | 1320 | 541 | 1092*314 | N*(3.2+X) |

| BK32-810 | DN150 | 0.96㎡ | 590 | 320 | 0.5/0.6 | 2086 | 640 | 1800 | 541 | 1572*314 | N*(3.2+X) |

| BK32-811 | DN250 | 1.10㎡ | 550 | 890 | 0.5/0.6 | 2110 | 895 | 1736 | 745 | 1406*420 | N*(3.2+X) |

| BK32-812 | DN250 | 1.70㎡ | 590 | 890 | 0.5/0.6 | 2704 | 895 | 2330 | 745 | 2000*420 | N*(3.2+X) |

| BK32-813 | DN350 | 1.74㎡ | 690 | 1800 | 0.5/0.6 | 2524 | 1136 | 2140 | 995 | 1692*559 | N*(3.2+X) |

| BK32-814 | DN350 | 1.70㎡ | 690 | 1800 | 0.5/0.6 | 3113 | 1136 | 2477 | 995 | 2029*559 | N*(3.2+X) |

| BK32-815 | DN500 | 2.40㎡ | 1250 | 3600 | 0.5/0.6 | 3257 | 1415 | 2503 | 1242 | 1898*712 | N*(3.2+X) |

| BK50-816 | DN100 | 0.52㎡ | 390 | 145 | 0.8 | 1712 | 535 | 1406 | 432 | 1227*257 | N*(5.0+X) |

| BK12-817 | DN200 | 1.00㎡ | 400 | 570 | 1.0 | 2205 | 760 | 1759 | 665 | 1526*404 | N*(12.0+X) |

|

Remarks: 1. The above product data is for reference only. The accurate product data is subject to the product design book and product drawings issued by our company. 2, the above products are the main product series of our company, our company can also provide other models of various models, please contact our technical department for consultation. |

|||||||||||

| Bink 1 series detachable plate heat exchanger product specification data sheet | |||||||||||

| 1 series product model | Take over | Area | Max pieces | Max flow | Plate thickness | Product height | Product width | Plate height | Plate width | Corner hole spacing | Clamping size |

| m³/h | mm | mm | mm | mm | mm | mm | mm | ||||

| BK20-101 | DN50 | 0.20㎡ | 280 | 36 | 0.5/0.6 | 970 | 320 | 797 | 248 | 690*140 | N*(2.0+X) |

| BK30-102 | DN50 | 0.19㎡ | 200 | 36 | 0.5/0.6 | 970 | 320 | 797 | 248 | 690*140 | N*(3.0+X) |

| BK25-103 | DN100 | 0.32㎡ | 380 | 145 | 0.5/0.6 | 1134 | 470 | 921 | 371 | 769*225 | N*(2.5+X) |

| BK40-104 | DN100 | 0.30㎡ | 270 | 145 | 0.5/0.6 | 1134 | 470 | 921 | 371 | 769*225 | N*(4.0+X) |

| BK25-105 | DN150 | 0.79㎡ | 690 | 320 | 0.5/0.6 | 1865/1990 | 610/650 | 1548 | 498 | 1344*298 | N*(2.5+X) |

| BK40-106 | DN150 | 0.79㎡ | 410 | 320 | 0.5/0.6 | 1865/1990 | 610/650 | 1548 | 498 | 1344*298 | N*(4.0+X) |

| BK40-107 | DN150 | 0.55㎡ | 410 | 320 | 0.5/0.6 | 1418/1543 | 610/650 | 1100 | 496 | 897*298 | N*(4.0+X) |

| BK20-108 | DN200 | 1.14㎡ | 680 | 570 | 0.5/0.6 | 2155 | 780 | 1795 | 620 | 1528*353 | N*(2.0+X) |

| BK40-109 | DN200 | 1.11㎡ | 400 | 570 | 0.5/0.6 | 2155 | 780 | 1795 | 620 | 1528*353 | N*(4.0+X) |

| BK40-110 | DN250/DN200 | 0.81㎡ | 630 | 890 | 0.5/0.6 | 1669/1815 | 920/927 | 2246 | 746 | 1013*439 | N*(4.0+X) |

|

Remarks: 1. The above product data is for reference only. The accurate product data is subject to the product design book and product drawings issued by our company. 2, the above products are the main product series of our company, our company can also provide other models of various models, please contact our technical department for consultation. |

|||||||||||